Black Dragon Autoclave 8 Litres Class B for Tattoo Studios

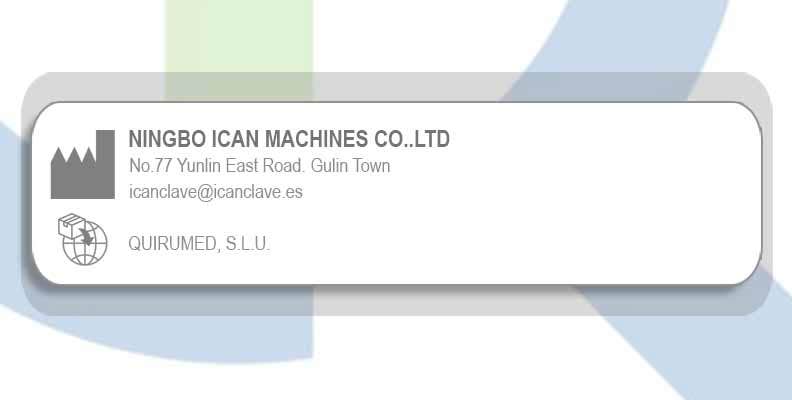

Manufacturer Information:

Name or company: Pending update

Email: Pending update

Postal address: Pending update

City: Pending update

Country: Pending update

Responsible person information:

Name or company: Pending update

Email: Pending update

Postal address: Pending update

City: Pending update

Country: Pending update

Warnings and product safety information:

The product complies with the General Product Safety Regulation.

Autoclave Black Dragon 8 litres class B for tattoo studios.

Programmes:

| Programmes | Temperature | Pressure | Sterilisation time | Total time | Type | Max. load | Max. load per tray |

|---|---|---|---|---|---|---|---|

| Solid | 134 ºC | 210 kPa | 4 min | 14-25 min | Solid unwrapped | 2 Kg | 0.60 Kg |

| 121 ºC | 110 kPa | 20 min | 25-40 min | ||||

| Wrapped | 134 ºC | 210 kPa | 4 min | 20-45 min | Solid unwrapped | 1.5 Kg | 0.60 Kg |

| 121 ºC | 110 kPa | 20 min | 30-50 min | Solid or hollow simple wrapped | 2 Kg | 0.60 Kg | |

| Liquid | 134ºC | 210 kPa | 10 min | 25-50 min | Liquid | 0.60 kg | 0.20 kg |

| 121ºC | 110 kPa | 30 min | 30-55 min | ||||

| Textile | 134 ºC | 210 kPa | 8 min |

25-50 min | Porous unwrapped | 0.50 Kg | 0.15 Kg |

| Porous simple wrapped | 0.35 Kg | 0.10 Kg | |||||

| 121 ºC | 110 kPa | 30 min | 30-55 min | Porous double wrapped | 0.25 Kg | 0.10 Kg | |

| Hollow simple wrapped | 1.5 Kg | 0.30 Kg | |||||

| Solid or hollow double wrapped | 1 Kg | 0.30 Kg | |||||

| Prion | 134 ºC | 210 kPa | 18 min | 30-50 min | Porous unwrapped | 0.50 Kg | 0.15 Kg |

| Porous simple wrapped | 0.35 Kg | 0.10 Kg | |||||

| Porous double wrapped | 0.25 Kg | 0.10 Kg | |||||

| Hollow simple wrapped | 1.5 Kg | 0.5 Kg | |||||

| Solid or hollow double wrapped | 1 Kg | 0.3 Kg | |||||

| B&D test | 134 ºC | 210 kPa | 3.5 min | 15-35 min | - | - | - |

| Helix test | 134 ºC | 210 kPa | 3.5 min | 15-25 min | - | - | - |

| Vacuum test | - | - | - | 17-20 min | - | - | - |

Safety:

- A cycle will not start unless the door is firmly closed.

- An automated system with double hydraulic locking device prevents the door from opening while chamber is pressurized.

- The safety valves prevent overpressure in the generator and in the chamber.

- A safety thermostat prevents overheating in the chamber and in the generator.

- An automatic safety lock prevents accidental opening of the door during the sterilisation. A power protector automatically cuts off power in case of short circuit or if power supply is not very stable.

- The failure alarm indicates a cycle failure and provides an error code.

- The door alarm indicates that the door is not properly closed.

- The low water alarm indicates when the water tank is empty or too full.

Technical features:

- Power supply: 220-240V; 50/60 Hz; 10A

- Chamber: 170 x 320 mm

- Breaker: F16A / 400V

- Nominal power: 1500VA

- 1500 VA

- Sterilisation temperature: 121 ºC / 134 ºC

- Capacity of the distilled water tank: 2.5 L

- Working temperature: 5 ºC / 40 ºC

- Working relative humidity: Max. 80%, non condensing

- Overall dimensions: 414 x 365 x 530 mm

- Net weight: 34.5 Kg

- Max. noise level: <70 dB

- Atmospheric pressure: 76 / 106 kPa

Components:

- Distilled water tank

- LCD display

- Control panel

- Main power switch

- Drain connector (distilled and used water tank)

- USB port

- Safety valve

- Ventilation grid

- Circuit breaker

- Power cable

- Rating plate

Accessories included:

- Steriliser

- USB

- 2 instrument trays

- Tray rack

- Tray holder

- Door adjustment tool

- 2 draining hoses

- Door gasket

- User manual

Standards:

- 93/42/EEC Directive on Medical Devices.

- 97/23/EEC Directive on Pressure Equipment.

- EN 13060 Small Steam Sterilisers.

- EN 61326, EN 61000 Electromagnetic Compatibility.

- EN 61010-1, UL 61010-1 Safety requirements.

- EN 61010-2-040, IEC 61010-2-040 Specific requirements for steam sterilisers used for treatment of medical materials.

In the UK this product needs to be inspected and certified anually. Quirumed don´t offer this service and you will need to find your own local techncian who can do this. We do however have a technical service based in Spain to cover the product during the warranty period

AUTOCLAVE - step by step:

1- Open the door, take the tools and accessories that are within the sterilisation chamber, remove the wrapper and clean them.

2- Connect the power cord to a suitable power source.

3- Connect the printer (optional. It is sold separately, ref. 922-PRINTER04).

4- Swith on: The main switch is located on the right bottom area in the front panel.

- Once activated, the LCD screen is on, where basic operation icons such as the position of the door, the water level, the sterilisation programme, date, time, etc. appear.

5- Fill tank with distilled water.

- Remove the top lid and fill, if you hear a signal, it means that you exceeded the permitted level of water in the tank, please stop immediately and drain the amount of water necessary for the signal off.

6- Preparation of instruments:

- Place instruments made of different materials in different trays, however take care to separate them before sterilisation.

- If the instruments are not stainless steel, put some sterilisation paper between the tray and the instruments.

- Do not allow direct contact between instruments of different materials.

- Verify that all instruments are in correct position.

- Place instruments such as lenses, containers, tubes, etc. inverted, so that water does not stagnate within them.

- Do not overload the trays beyond their limit.

- Do not overlap the trays on top of each other, or put them in direct contact with the wall of the sterilisation chamber.

- Do not use metal clips or pins, this may impair the operation of the steriliser.

- Wrap the instruments one by one. If you need to wrap several instruments together, make sure that they are made of the same material.

- Seal the pouch with special adhesive tape for sterilisation or use a heat sealer.

- Make sure that the pouch is properly positioned within the chamber on the trays (resting on the plastic part).

7- Choose the sterilisation programme.

8- Start the sterilisation cycle.

- After selecting the sterilisation programme, insert instruments into the chamber on the trays, using the supplied plastic handle.

- Once the instruments are placed within the chamber, close the door by turning the knob.

- Caution: make sure to close the door, otherwise the steriliser displays an alarm and can not start or the programme stops during the cycle.

9- Start the sterilisation programme.

- Press the start button, then the steriliser starts operating during approximately 30-75 minutes.

10- Sterilisation cycle finished.

- After finishing the sterilisation cycle, the printer (not included*) will print the full report automatically and the data will be saved in the USB memory (.txt format).

- After the pressure drops to zero, you can open the door and remove the instruments. The steriliser alerts by a beep once the sterilisation cycle is completed.

- Caution: Use the supplied plastic handle for supporting trays when you take out the instruments.

IMPORTANT: Do not reuse used water.

Installation:

- There must be at least 10 cm of free space around the steriliser, 25 cm at the top, and enough room to open the door.

- The place where the steriliser is used must have proper ventilation.

- The steriliser must be placed on a stable surface and at an appropriate height for handling.

- Do not cover or block the lateral outlets or the outlet air grid of the condenser fan.

- Do not place the steriliser near water sources.

- Keep away from heat sources.

Example of printed report:

================================

Programme: WRAPPED

Temperature: 134C

Pressure: 206.0 kPa

Drying time: 08min

Sterilisation time: 4.0Min

--------------------------------

Time Temp. pressure

Start 12:28:17 089.0C

T1: 12:31:32 087.1C -075.0kPa

T2: 12:33:43 110.2C 052.0kPa

T3: 12:36:37 088.9C -080.0kPa

T4: 12:39:20 114.7C 053.7kPa

T5: 12:43:37 087.9C -080.0kPa

T6: 12:50:40 134.8C 206.0kPa

TS: 134.7C 209.5kPa

Max. Temperature: 135.2C

Min. Temperature: 134.3C

Max. Pressure: 214.0kPa

Min. Pressure: 204.9kPa

T7: 12:54:39 134.4C 211.4kPa

T8: 12:57:36 102.1C -060.0kPa

T9: 12:59:54 098.2C -060.0kPa

End 13:04:07 102.4C

--------------------------------

Cycle No .: 00017

Result: success

Date: 07/06/2014

SN: E54723

operator:

================================

Video:

continue in UK

continue in UK Ireland

Ireland